Padeswood

Padeswood-prosjektet er forventet å kutte CO2-utslipp med 800 000 tonn årlig, dobbelt av Brevik CCS

Heidelberg Materials takes the next step with CCS – Final Investment Decision in the UK

Heidelberg Materials has taken the Final Investment Decision to build a full-scale carbon dioxide capture facility at its cement plant in Padeswood, Wales. The facility, which is expected to be completed in 2029, will capture nearly 800,000 tons of CO₂ per year – essentially the entire plant's emissions – and deliver evoZero which enables zero-net-emission concrete to customers across Europe.

Padeswood will become the company's second industrial-scale CCS facility in the cement production.

The first is Brevik CCS in Norway, which was inaugurated in the summer of 2025. Brevik is the world's very first industrial CCS facility in cement and is a pioneer paving the way for the entire industry. The experience and lessons learned in Brevik – from technical integration to operational and commercial aspects – will now be a direct asset in Padeswood.

Padeswood CCS will capture almost all CO₂ emissions from the cement kiln and the combined heat and power plant. The plant also has the potential to become a carbon sink, as the emissions captured from the kiln include CO₂ from biofuels – materials from plants that have absorbed CO₂ during their life cycle. When these carbon dioxide emissions are captured and stored, the total amount of CO₂ in the atmosphere is reduced and a carbon sink is created.

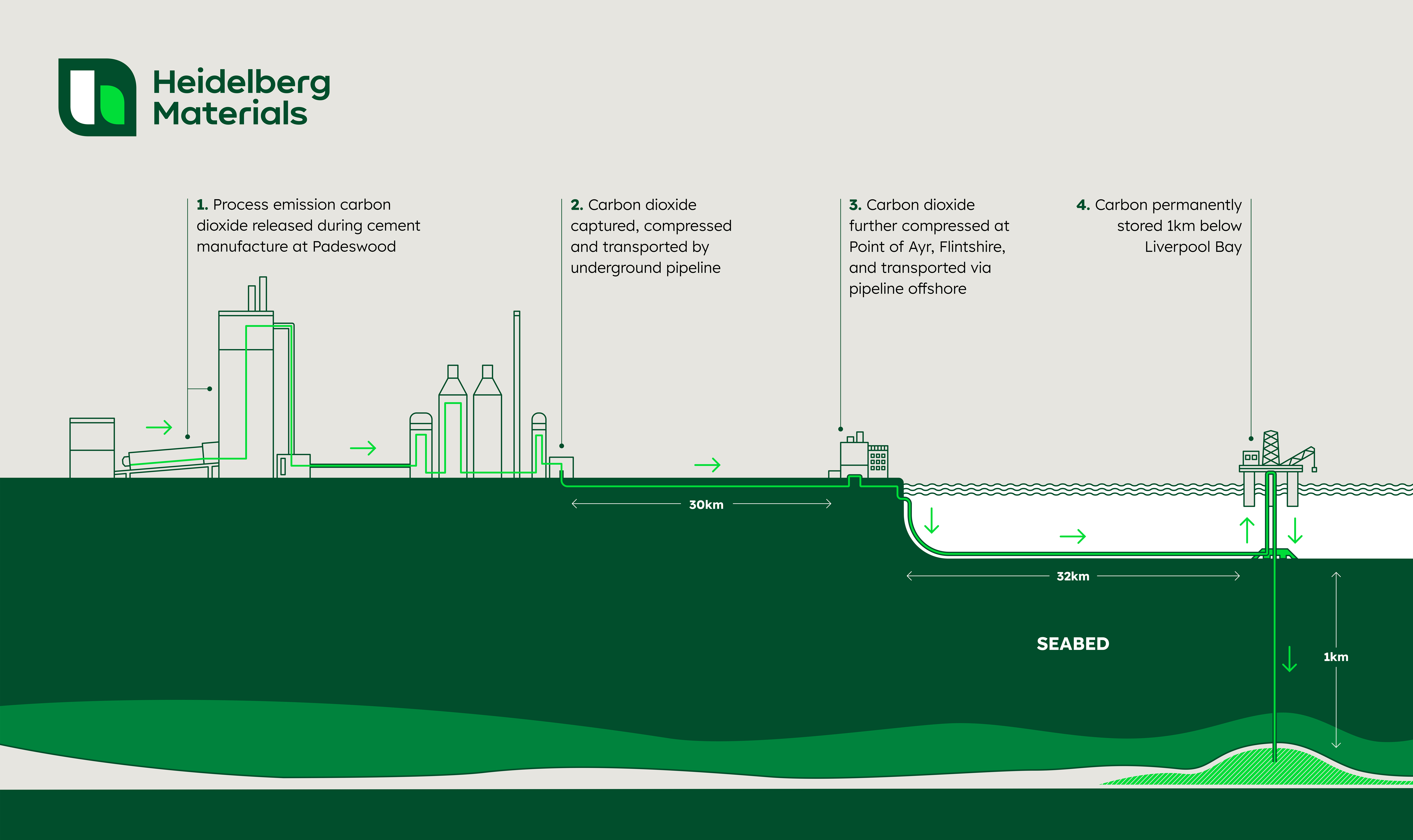

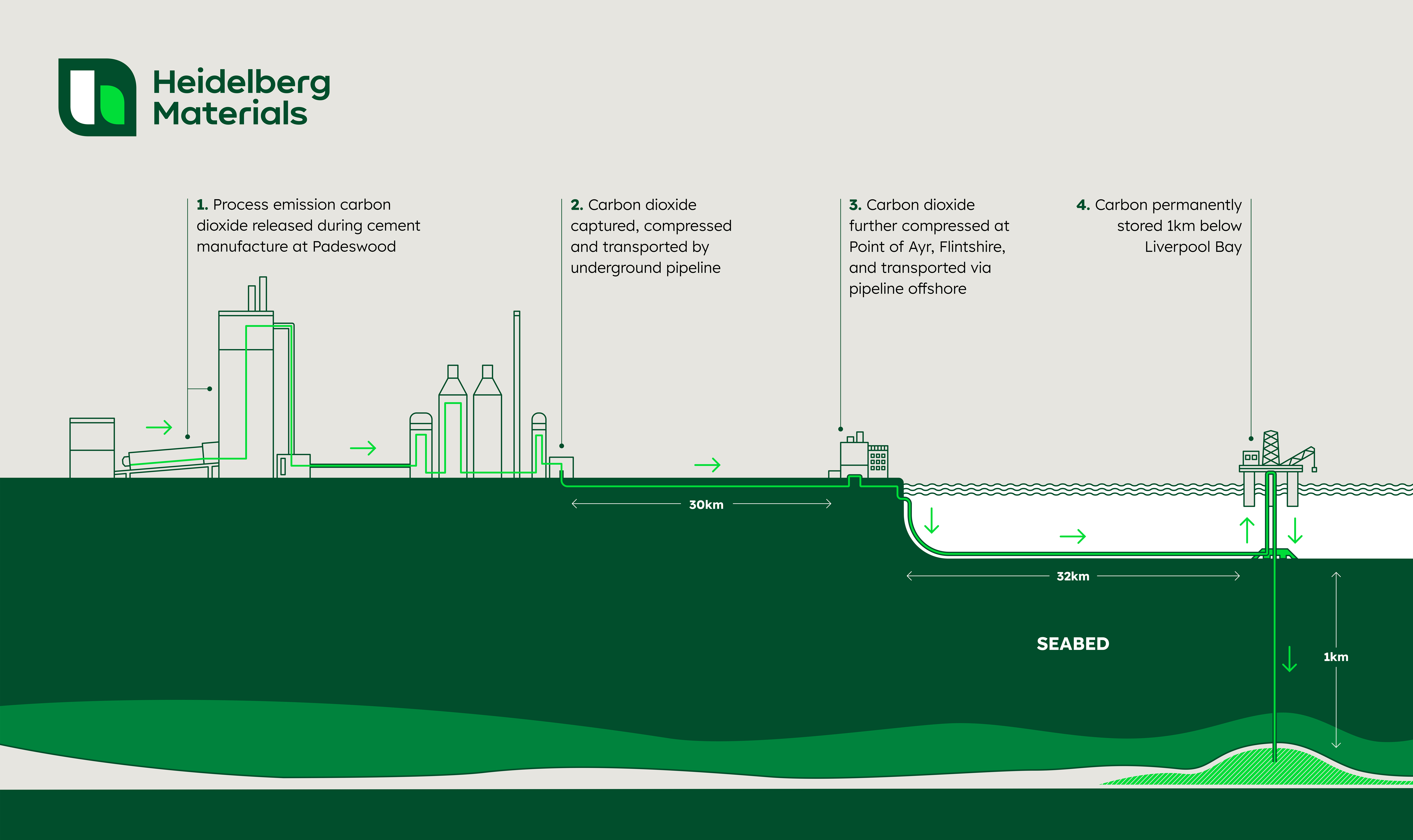

Construction of the CCS facility at the Padeswood plant will begin later this year, with commissioning planned for 2029. Captured CO₂ will be compressed and transported via an underground pipeline for safe storage under the seabed in Liverpool Bay as part of the HyNet North West project. Padeswood CCS is expected to bring significant economic benefits to North Wales: over 200 jobs will be secured, around 50 new jobs will be created, and up to 500 jobs will be created during the construction period.

Heidelberg Materials has a number of projects in which industrial-scale CCS solutions are being developed. One of Europe's largest CCS projects is under development in Slite on Gotland. The facility will be able to capture up to 1.8 million tons of CO₂ per year, making the project one of the most significant climate initiatives in Europe.

Statements from Heidelberg Materials Northern Europe

Giv Brantenberg, General Manager, Heidelberg Materials Northern Europe, says:

"With the final investment decision for Padeswood now in place, Heidelberg Materials demonstrates that we truly walk the talk. Brevik CCS was always meant to be the starting point – and Padeswood now proves that our commitment is becoming reality. The practical experience and lessons learned from Brevik were decisive in the assessment. It reduced technical and operational uncertainty and helped accelerate a robust plan for Padeswood that delivers deep decarbonization.”

Giv Brantenberg added:

"This step is not just about building another capture plant. It is about scaling a solution that makes carbon captured net-zero cement commercially available at industrial scale. Padeswood will significantly increase evoZero supply across Europe and demonstrate how learnings from one project can be transferred rapidly to deliver repeatable, high-impact decarbonisation.”

Karin Comstedt Webb, Vice President of Heidelberg Materials Sweden, says:

“With Brevik, we're showing that CCS works in practice, and in Padeswood, we're scaling the technology to the next level.” Our focus now is on achieving the conditions for investment as soon as possible in Sweden as well. Slite CCS ensures future competitiveness in the cement industry and, thereby, domestic cement supply and preparedness over time.

Slite CCS represents a reduction equivalent to 4 percent of Sweden's total carbon dioxide emissions, making it an important component in achieving national climate goals. The project is also crucial for the construction sector to achieve its goal of net-zero emissions.

Through Brevik and Padeswood, Heidelberg Materials is consolidating its leading role in the global transition of the cement industry. Together, these projects make it possible to offer evoZero and other climate-enhanced building materials on a large scale.

More info here:

CCS project: Final Investment Decision | Heidelberg Materials

3_Padeswood CCS_HyNet Infrastructure.jpg.

HeidelbergMaterials

2_Padeswood CCS process diagram.jpg.

HeidelbergMaterials

Brevik CCS.

1_Heidelberg Materials Padeswood cement plant.

HeidelbergMaterials

3_Padeswood CCS_HyNet Infrastructure.jpg.

HeidelbergMaterials

2_Padeswood CCS process diagram.jpg.

HeidelbergMaterials

Brevik CCS.

1_Heidelberg Materials Padeswood cement plant.

HeidelbergMaterials